Selecting tape is like filling out a multiple-choice exam: choose wrong and you’re in for a bad time. Not all tapes are equal. Some tapes can stand up to the tasks of shipping and storage, and some can’t. And even if your tape can seal cartons, you may not be applying it right.

The following are four of the most common mistakes made when handling tape. If you find yourself making any number of these mistakes, you may need to rethink how you buy and use tape.

1. Choosing the Wrong Tape

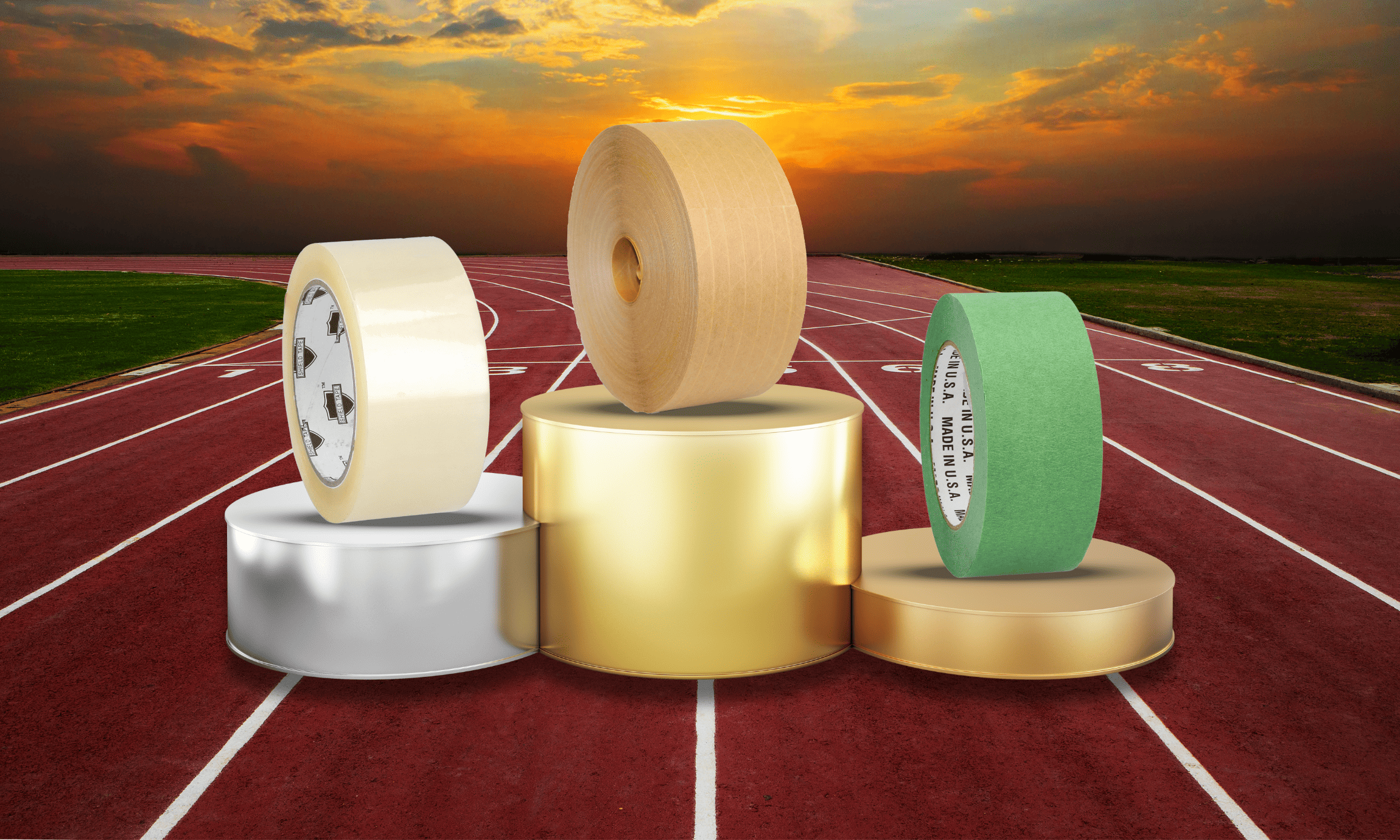

This is the big one. If you’ve got the wrong tape for the job, you don’t even have a chance of completing it successfully. Different tapes offer different features and differing levels of stickiness.

When it comes to sealing boxes, standard carton sealing tape or kraft tape will do the job. Just make sure it’s the right width for the box you’re sealing and avoid tapes that are either too wide or too narrow. Additionally, make sure you stay aware of the tape’s strength. Lighter, thinner tapes are best for lightweight loads, while heavy and thick tapes work well for heavy-duty loads.

To learn more about pressure sensitive carton sealing tape and water-activated kraft paper tape, take a look at our article going over their characteristics and comparing them side-by-side.

2. Applying the Tape Incorrectly

Once you ensure that you’re using the right tape, now make sure you’re using it correctly. Apply the tape in a straight line and firmly press it against the box. If there is any excess tape, cut it off with a pair of scissors so your packaging looks neat and tidy. For extra security, use the H-shape method: apply the tape across all open seams across the top and bottom, forming an H-shape with your tape on both sides:

Avoid having your tape touch your products; this will ensure that your products are undamaged and are not covered in adhesive residue. Furthermore, don’t handle tape below 32°F, or 0°C, or the adhesive may not work properly and hold its cling when applied to the package.

You can follow along to our step-by-step video on taping boxes here:

3. Not Using Enough

Using a lot of tape can be expensive, but do you know what’s more costly? Product damage. Therefore, don’t be too sparing when using your tape. Apply your tape in perpendicular directions to maximize the security of your package.

If you’re using a dispenser, ensure the tape is fully extended before pressing it against the box. This helps to guarantee that there’ll be enough adhesive on the tape to keep it in place.

4. Not Using the Right Color

This may seem like a lesser concern than the last three, but a little detail like this goes a long way. When it comes to your packaging, it's important to choose a tape color that matches your brand. For example, if your company is typically associated with the color red like Target or Nintendo, stock up on some red packaging tape. This helps to raise brand awareness and promote brand recognition. The color of the tape can also help you organize and identify packages that need to be shipped out sooner than others.

Nobody’s Perfect

If you’ve made any of the four previous mistakes, it’s okay—you’re only human! Tape is a more complicated category of packaging supplies than you might realize, with a diverse collection of tapes of different sizes, properties, and strengths. Knowing what certain kinds of tape can and cannot do is half the battle, while knowing how to properly apply them is the other half. If you feel lost or confused, do not hesitate to reach out to your packaging supplier and arrange a consultation.

While you’re still here, be sure to check out our wide selection of wholesale packing tape. We offer free shipping on all our tape products, so let us be your stepping stone into the world of better and stronger tapes.

Log In