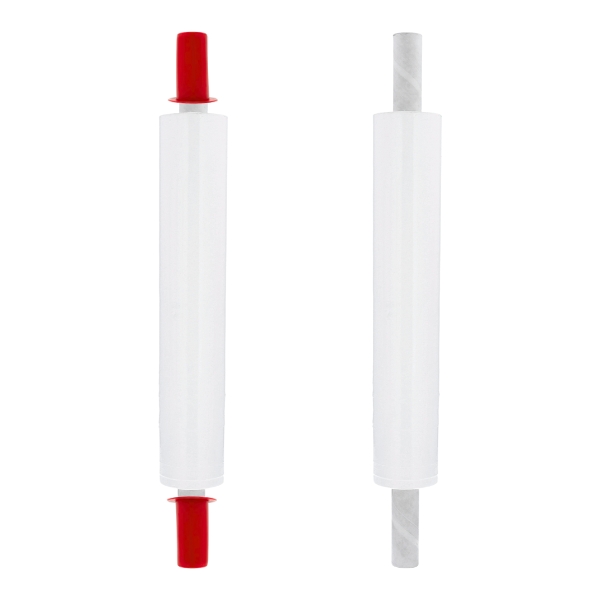

Selecting the right pallet stretch wrap is crucial for ensuring load stability and protection during transportation and storage. Start by evaluating the weight and shape of your pallets. Heavy or irregularly shaped loads typically require a stronger, higher-gauge wrap, like blown stretch film, which offers superior puncture resistance.

When selecting Pallet Stretch Wrap, consider your load weight, wrap volume, and application method. Lighter loads may benefit from Cast Extended Core Pallet Stretch Wrap due to its clarity, quiet unwind, and ease of manual use. For higher throughput or automated systems, Performance Pallet Wrap offers superior load retention and tear resistance, ideal for stabilizing heavier or irregular shipments. Choosing the right stretch film for hand use ensures secure transport, reduces material waste, and enhances overall packaging efficiency.

Sign In