Tape is tape, so as long as it sticks to the box, it’ll keep it closed and there’s nothing else to worry about, right? Wrong. Choosing the wrong kind of tape for the job can have disastrous results. Not all tapes can equally withstand the rigors of shipping and handling, volatile and extreme changes in temperature and humidity, and the effects of long-term storage. A package sealed with the wrong tape is in danger of accidentally opening up and spilling its contents, exposing them to environmental contamination.

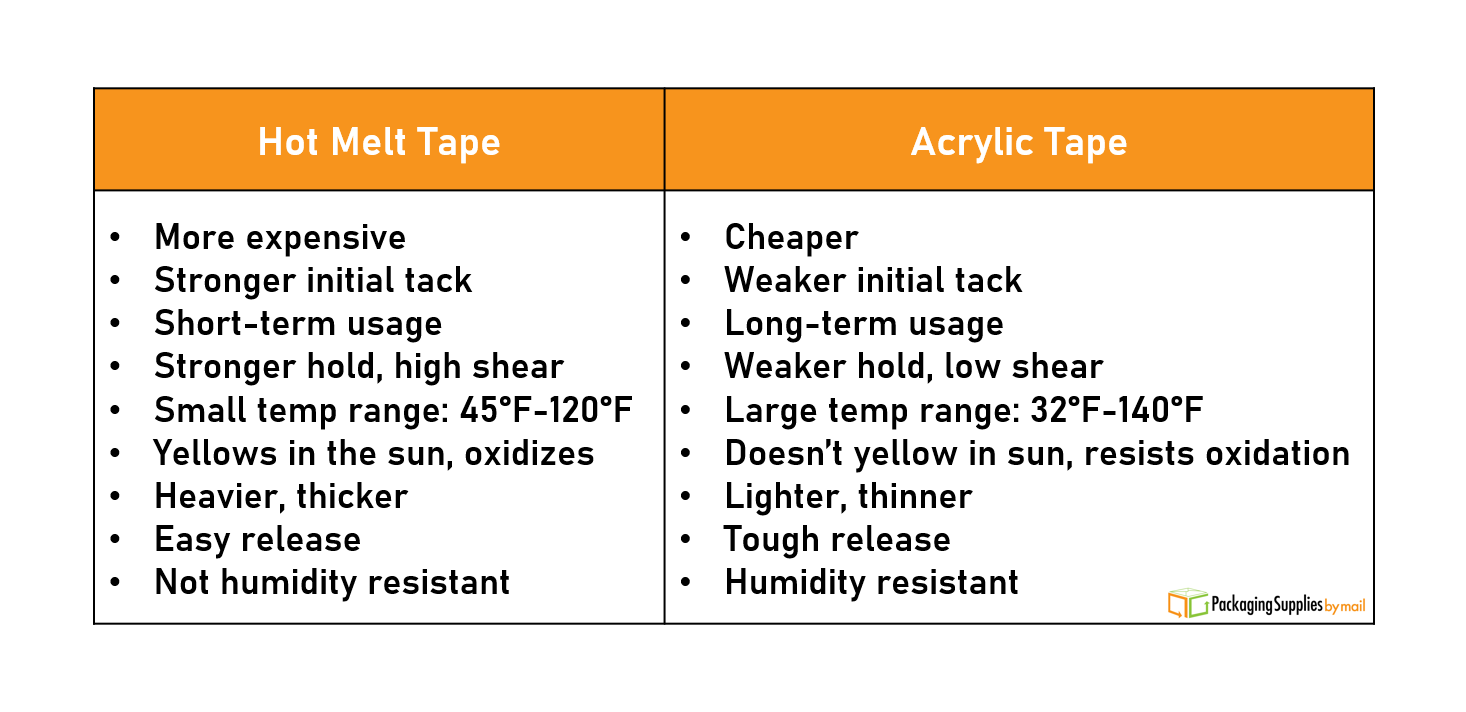

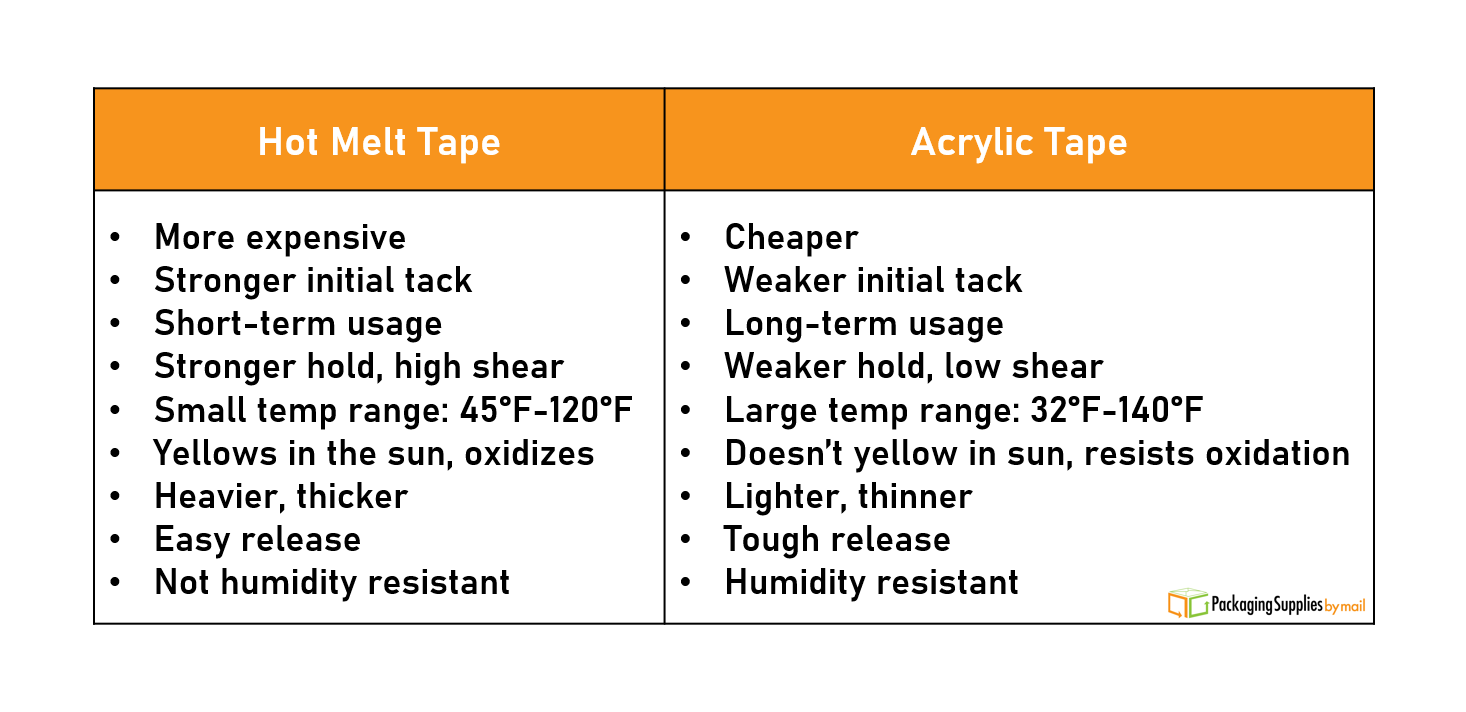

Thankfully, when it comes to sealing packages and cartons, there are two main types of packing tape that you need to consider: hot melt and acrylic. These tapes may share some similarities – they are both clear or brown tapes that are primarily used for sealing boxes, cartons, and other kinds of packaging – but make no mistake, these two kinds of tapes have several key differences that set them apart. So let’s dive in and see how the two types of tape compare and contrast with each other, starting with…

Hot Melt Tape

Hot Melt Tape is manufactured from thermoplastic polymers with a synthetic rubber adhesive coating applied to one side. Hot melt’s primary advantage is its strong, instantaneous cling. The rubber adhesive has a stronger initial tack than acrylic, so it performs better with heavier, overstuffed loads. The tape is thicker and heavier, and releases easily and consistently from the roll during use. It is also compatible with a wider range of surfaces, including rough, recycled, and low-energy surfaces.

However, hot melt is more expensive than acrylic. It also performs worse in high humidity and extreme temperatures; anything outside of the 45°F to 120°F (8°C to 48°C) range and it starts to fail. When exposed to UV light, the tape yellows and oxidizes. On top of this, hot melt tape works better for short-term use and degrades over the long term.

Acrylic Tape

Acrylic Tape is made from acrylic resins coated with a layer of an acrylic emulsion adhesive. Acrylic has two distinct advantages over hot melt. First, it is the more cost-effective tape of the two. Second, it performs better in extreme conditions. It has a wider temperature range at 32°F to 140°F (0°C to 60°C) and maintains its hold in high humidity. Also, unlike hot melt, acrylic tape does not yellow and oxidize when exposed to the sun’s UV rays. Additionally, acrylic develops its adhesion over time, making it ideal for long-term use.

Despite these advantages, acrylic is generally a weaker tape when compared to hot melt. It’s lighter and thinner and has a weaker initial tack than hot melt. The tape is tougher to release from the roll and its weaker, less consistent adhesion makes it compatible with fewer surfaces. While acrylic may perform well enough in most applications, hot melt is the better solution for heavy-duty and irregularly-shaped loads.

Which Tape Do I Use?

Now that you know what each type of tape is and what they do, which one do you choose? Frankly, it depends on what’s required for the job and the size of your budget.

Hot melt is a robust tape with a strong cling and easy release, making it ideal for heavy-duty applications. Hot melt excels with loads that are expensive, overstuffed, and/or irregularly-shaped. However, hot melt suffers when exposed to the elements or when used in the long term. Also, hot melt is decidedly the more expensive option, so this will need to be considered in your budget.

Acrylic is the cheaper of the two, which makes it the more budget-friendly choice. As a light tape with an average cling, it works well for many applications, but perhaps not the most demanding ones. Acrylic shines in extreme environments, where it performs better than hot melt in high humidity, extreme temperatures, and exposure to UV light. Additionally, acrylic’s adhesion strengthens over time, making it the preferred option for long-term storage.

For further information on the factors that determine how well these tapes perform in given circumstances, be sure to check out this Packaging Strategies article that breaks down their differences and highlights key characteristics like substrate and application method.

We here at PackagingSuppliesByMail offer both hot melt and acrylic tape to meet all the demands of the job. Our hot melt tapes range from 1.5 mil to 3.46 mil in thickness, while our acrylic tapes are available from 1.6 mil to 3.0 mil. We also offer many other kinds of tape, including duct, painter’s, caution, double-sided, and more. So make us your number one choice for all your tape and packaging needs.

Sign In