If you do a lot of business by mail, ask yourself: are you using the strongest, most durable, and most convenient packing tape? Your two primary choices boil down to pressure sensitive and water-activated tape. Both have their benefits, and it may be best to have both on hand in case of unexpected developments. But when it comes down to specific jobs, it’s worth reviewing which is best for certain kinds of tasks.

Pressure Sensitive Tape (PST): Cheap and Easy

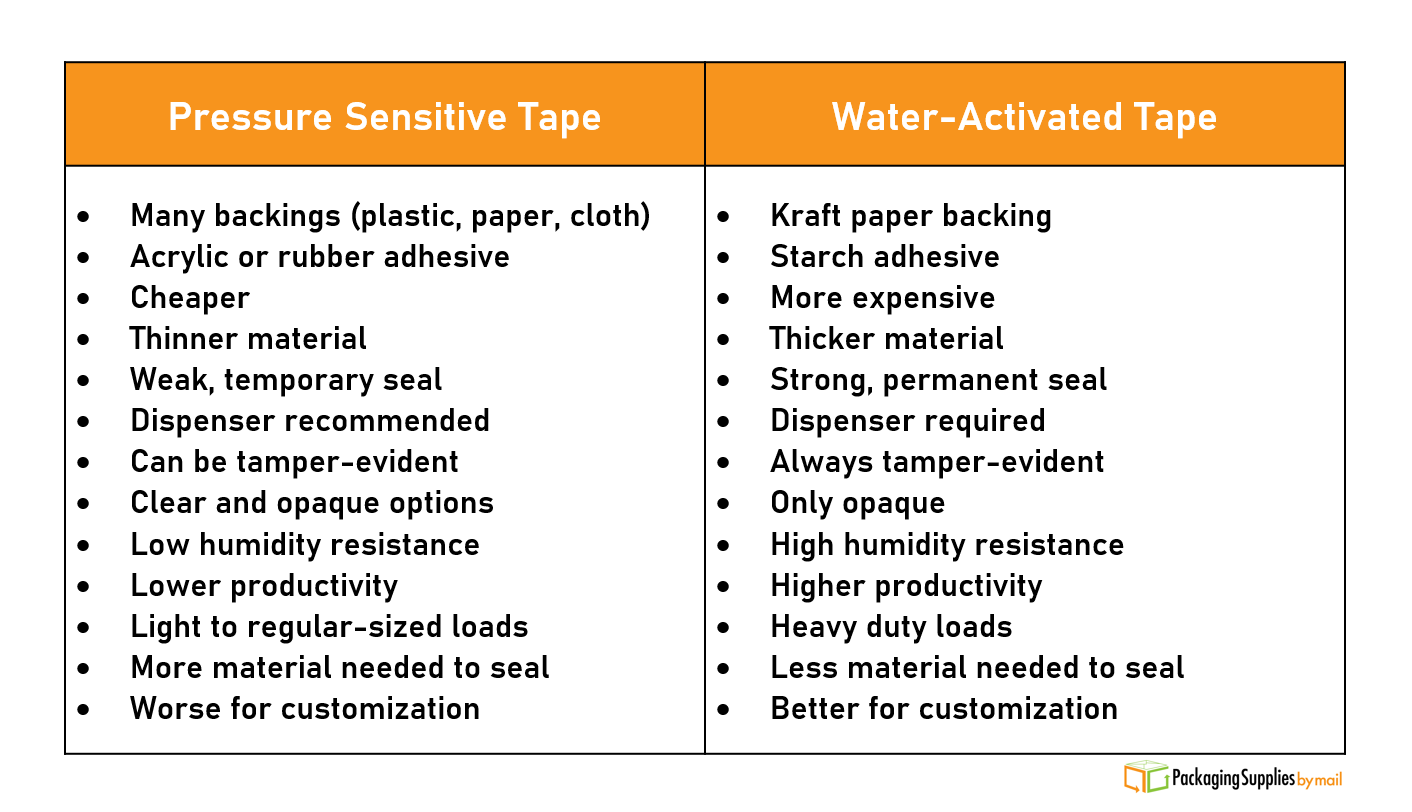

Most tapes that you’ll come across are pressure sensitive. Just as the name suggests, this tape is secured to surfaces with an application of light pressure. The backing is a long strip of plastic, paper, cloth, or another material that is coated on one side with a layer of adhesive. The adhesive is usually made from either acrylic resin or rubber; acrylic is more cost-effective and performs better in extreme environments, while rubber has a stronger tack and can support heavier loads.

Pressure sensitive tape comes in several varieties, including masking, filament, and duct tape. For the sake of this article, however, we will be focusing on carton sealing tape. This is one of the most common types of tape out there, primarily used for sealing packages and boxes for shipping. Carton sealing tape is made from a plastic backing and provides a secure and durable seal on cartons. This tape can be used with a tape dispenser for increased efficiency.

Water-Activated Tape (WAT): Quick and Strong

Water-activated tape, also known as gummed tape, is exactly what it sounds like: an adhesive tape that needs water to become sticky. While pressure sensitive tape is made with a large assortment of backings, water-activated tape is exclusively manufactured with a kraft paper backing; this brown, high-strength paper enhances the tape’s tensile strength. The kraft paper backing is coated on one side with a layer of a starch-based adhesive. When this adhesive is brushed with a layer of water, it activates and is immediately ready for sealing.

Some water-activated tapes feature additional reinforcement in the form of thin fiberglass strands running down the length of the tape, boosting the tape’s already high tensile strength. No matter the kind of tape, however, water-activated tapes require a special dispenser with a set of sponges/brushes that apply the layer of water. Advanced dispensers allow you to set your desired length of tape, adjust your moistening level, and even provide automatic settings.

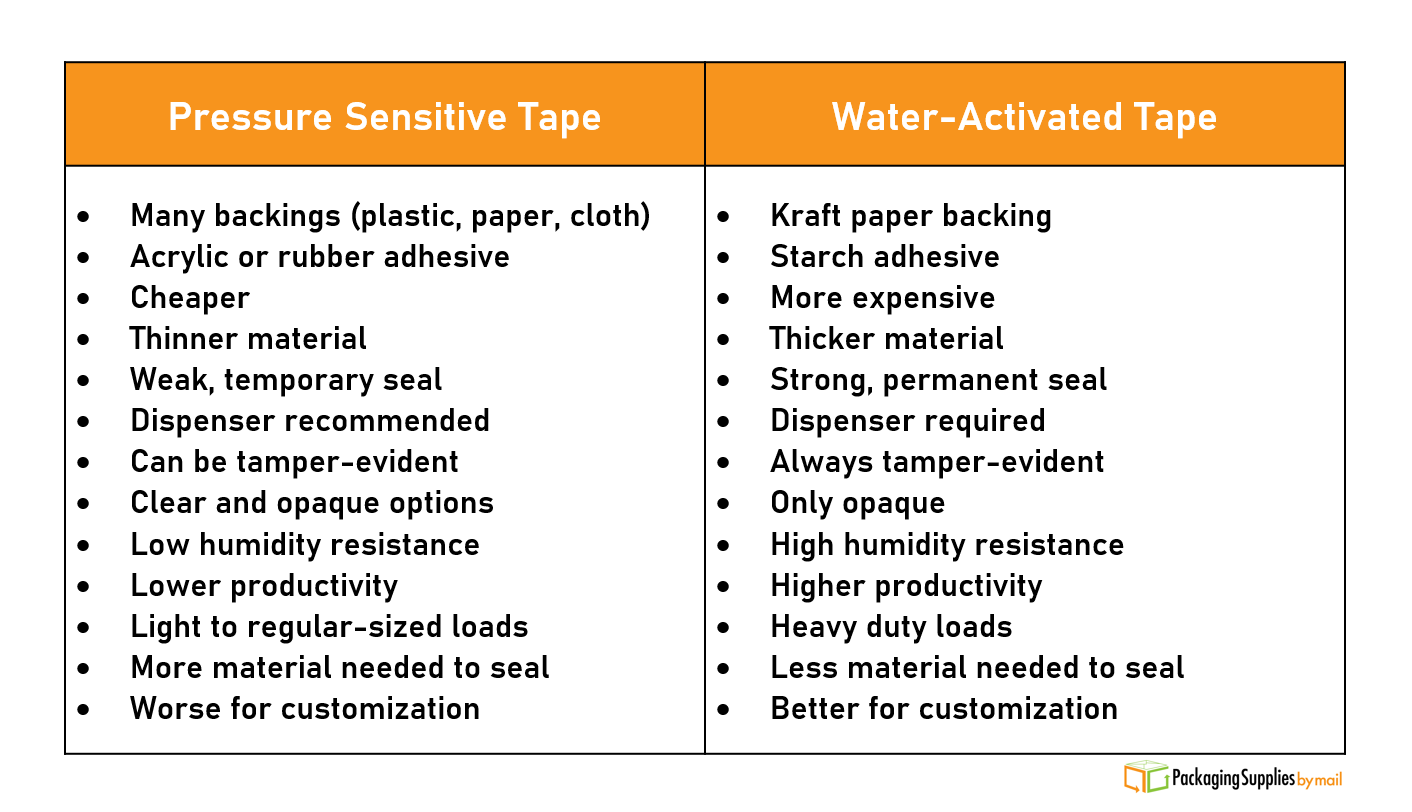

Pros and Cons

Now that we’re familiar with each type of tape, let’s see how they compare side-by-side.

Pressure sensitive tape’s primary advantage is that it is more cost-effective upfront. The average roll of water-activated tape generally costs more than a pressure sensitive roll. Furthermore, water-activated tape requires an expensive specialty dispenser to function, while a manual tape gun is much cheaper, not to mention that no dispenser is free. Pressure activated tape is available in a wide variety of different types and color options to serve a multitude of applications.

Despite these benefits, pressure sensitive tape comes with a few drawbacks as well. Compared to water-activated tape, pressure tape has a weaker tack and lower tensile strength. Because the material is weaker, more tape is needed to properly seal cartons, resulting in higher waste and lower efficiency. Additionally, plastic-backed tapes are not the best for stamping with brand information.

Water-activated tapes are renowned for their robust adhesion and excellent tensile strength. When activated with water, the starch-based adhesive becomes so strong that, when set in place, it penetrates the fibers of the carton, effectively fusing with the package. Water-activated tape cannot be removed from cartons without damaging them, making the tape a great means of tamper-prevention. Compared to pressure tape, water-activated paper tape performs better in environments with high humidity and extreme temperatures, and the kraft paper material is much more conducive for branding efforts.

For more information about the benefits of gummed paper tape, be sure to check out our article going over the top 8 reasons to seal your packages with it. Alternatively, we recommend taking a look at this Tape University article discussing water-activated tape’s use in e-commerce.

Unfortunately, water-activated tape (including dispenser) costs more upfront than pressure tape; however, since the tape is stronger, less of it is needed to seal packages, thereby lowering waste and boosting productivity. On top of this, while water-activated tape outperforms pressure sensitive tape in nearly every way, gummed tape may be overkill for what you need. If you need tape around the house simply to make quick fixes, seal envelopes, or wrap gifts, you might be better off sticking with conventional pressure sensitive tape.

As you can see, there are key differences between pressure sensitive and water-activated tape that set them distinctly apart. While gummed tape is a superior choice to pressure tape in nearly every facet, pressure tape may be a better choice for cheap and simple applications. Be sure to take a look at our selection of tapes and see what will work for you. With free shipping on all bulk orders of tape products, we at PackagingSuppliesByMail can guarantee your packages will be sealed and protected throughout shipping, storage, and delivery.

Sign In