Rust is the archnemesis of metal. If you are shipping metal goods, you need to ensure that these items are protected from corrosion. But how? If you need to protect something from water, you put it in waterproof packaging. If you need to protect something from ultraviolet light, you store it in a dark setting. But the elements that corrode metal are all around us. What’s to be done?

Thankfully, the answer is easy: get yourself some VCI stretch wrap! Short for Volatile Corrosion Inhibitor, VCI film is an excellent way of protecting metal against rust. On top of this, the material is also resistant to tearing, splitting, moisture, and common contaminants like dust and dirt. In this article, we will explore what VCI is, how it works, and why you should start protecting your metal products with it today.

What is VCI?

Also known as Vapor Corrosion Inhibitor, VCI is a revolutionary technology that stops the spread of rust on metal surfaces. VCI can take many different forms, including paper, liquid resin, foam, and for the sake of this article, plastic film. No matter the form, the VCI material is chock full of corrosion-inhibiting molecular compounds that are electromagnetically polarized.

How Does VCI Work?

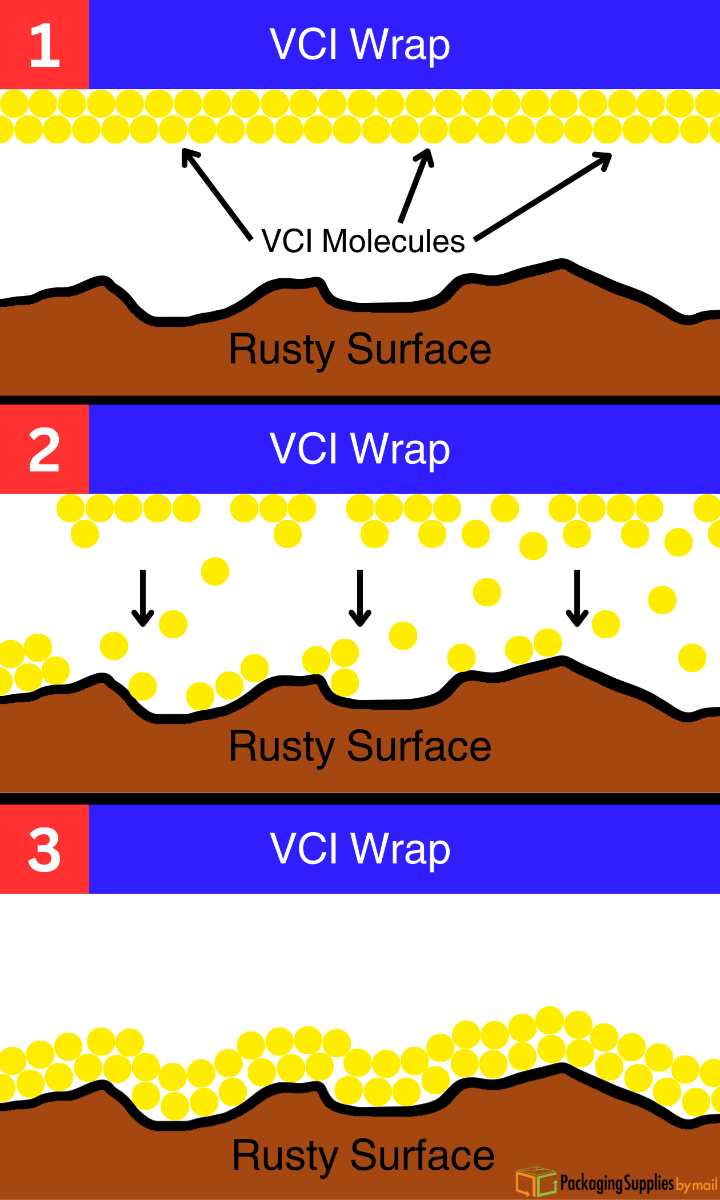

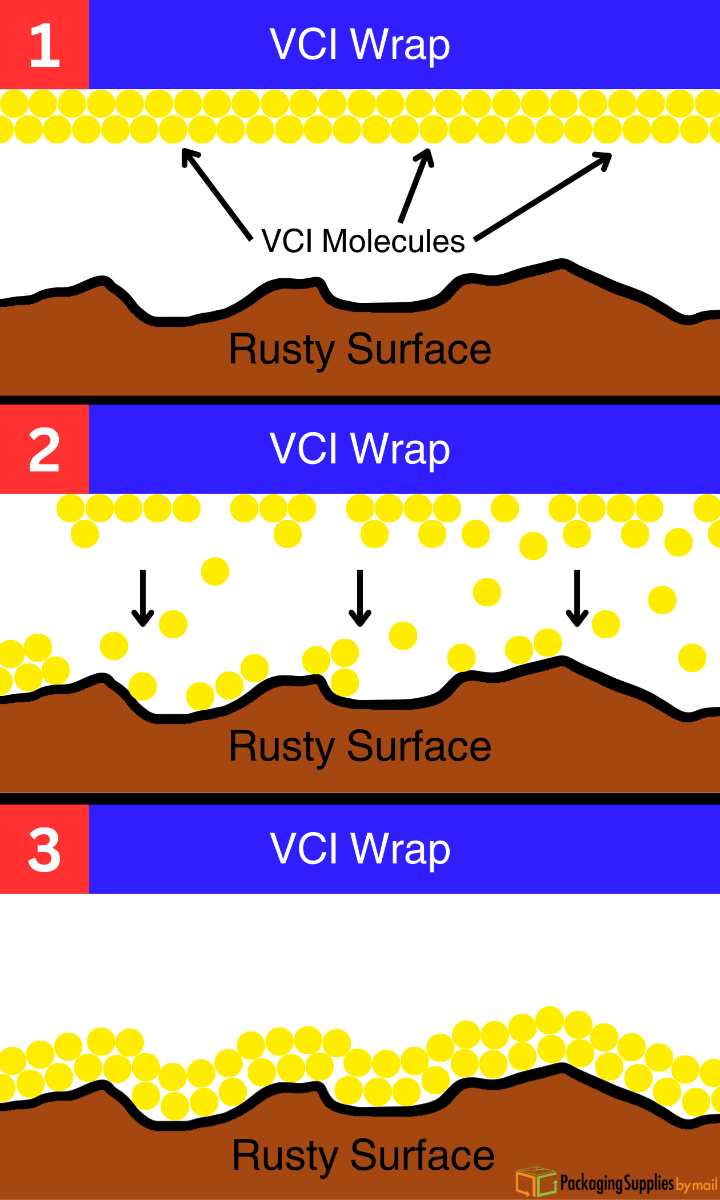

VCI material protects metal surfaces through three basic steps, as the following infographic demonstrates:

Step 1: The VCI stretch wrap comes covered in a layer of corrosion-inhibiting molecules.

Step 2: When the VCI film is wrapped around metal objects, the molecules vaporize from the film and are magnetically attracted to the metal surface.

Step 3: The molecules pile onto the metal, forming a protective barrier that prevents oxidation. The VCI molecules fill in every nook and cranny on the metal surface until a continuous protective barrier has been formed. With the barrier in place, rust cannot form and corrosion is halted.

What is VCI Best Used For?

VCI wrap is best used for items that are sensitive to environmental corrosion, including:

Electronics

Tools

Circuit Breakers

Computers

Automotive Parts

Control Panels

Switches and Valves

How Do I Use VCI Wrap?

Because VCI works by emitting a vapor of molecules that form a protective layer, VCI will perform best in an enclosed space. Therefore, wrap your item in some VCI corrosion protection film, then place it in an enclosure, such as a box, a sealable bag, or even a desk drawer. For extra security, you may want to seal your enclosure with a few strips of carton sealing tape to render it airtight.

While VCI film contains electromagnetically charged molecules, the wrap is thankfully safe to use. VCI emitters do not contain any chemicals known to be toxic or flammable. In fact, the FDA has approved VCI to be used in packaging for food and beverage.

VCI wrap works like standard stretch film. Simply assemble your items together, then tightly wrap them up in the plastic film. The palletized items stay together as a solid unit and are protected from contaminants like dust and moisture. VCI film is tinted bright blue for easy identification and organization.

We at PackagingSuppliesByMail offer a wide variety of specialty stretch wraps, including VCI film in hand wrap and machine length sizes. All of our stretch wrap products come with free shipping, so let us be your first step into the world of VCI. By bundling loads together and protecting them from corrosion and contamination, VCI wrap proves to be one of the most important pieces of packaging that you can keep around.

To learn more about our speciality stretch wrap, be sure to check out our article about netting wrap, which covers what it is and what it is used for.

Sign In